1 Ton Cement Bags/Bulk Bags - How to unload them effortlessly!

So you are considering the benefits of purchasing bulk cement or cement in a Bulk Bag - FIBC (Flexible Intermediate Bulk Container). There are of course many benefits in doing this, some of which are listed below. We also need to consider the drawbacks and find the balance between the two and decide "is it for me"?

Without a doubt handling a FIBC has financial impact both positively and negatively. You will need to consider the processes that your materials need to take.

In this example we look at the path Cement will take in the process of making concrete, we also talk about a Concrete Pan Mixer for mixing the cement and other materials.

Cement need to be unloaded off a lorry and then stored in a secure dry warehouse otherwise your product may quickly deteriorate, go to waste or absorb moisture from the surrounding air.

You will then need to look at how to best get the cement from the bag into the concrete mixer. There are many types of FIBC's, but the two main types you need to consider are flat bottom bags or bags with a skirt. If you are not using a Bulk Bag Unloader then the best bag to use is most likely to be the skirted bag.

A skirted bag (shown above) will allow you to raise the bag above the Pan Mixer and unload the Bulk Bag or part of it into the mixer. The skirt is tied off to ensure the product does not unexpectedly flow out.

The problem with unloading like this is that often you will have to be underneath the Bulk Bag to untie the bag or to unload it which adds a risk to both yourself and or your staff. One way to avoid these risks is to invest in a Bulk Bag unloader.

Bulk Bag unloaders come in many varying shapes and sizes but ultimately they have 3 key components which are. Cruciform ( Bag Holder), Bag Discharger/Unloader and the Screw Conveyor to transfer the unloaded product back to the desired height or position.

By using a Bulk Bag unloader you can get multiple benefits some of which are:

- Increased safety while unloading

- Reduced labour

- Increased output

- Potential to reduce dust during discharging

- Consistent flow of product

In summary they way to unload a bulk bag effortlessly is by using a Bulk Bag unloader. The question though is is it worth the investment? You will only know that if you know the price, so we address that here and now!

You can expect to pay in the range of £7995 - £15,497+VAT for a Bulk Bag unloader which would be a simple model with no extra configurations. If you wanted to optimise you production and processes to get even greater outputs then you can add on some on the following options.

- Vibration motor to help product flow for those product s which are stickier and tend to clump together.

- Pneumatic petals to help massage the product out of the bag.

- Weigh cells to give live reading of product left in the bag

- Batch Control System which will allow you to choose a weight and press start, once the Xtractor Bulk Bag unloader has reached the desired weight then it will stop and wait for next instruction.

- Gantry crane for lifting and loading Bulk Bags (instead of forklift and cruciform). This is often a preferred method when space is not readily available.

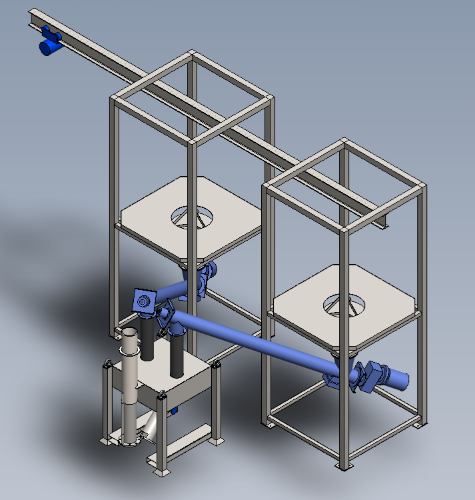

Below is a configuration of a recent solution for a client who needed to safely process two minerals from bulk bags and then into another mixing process. We designed and configured this solution to enable safe movement of materials, removal of manual handling and product cost reduction due to bulk delivery discounts.

This solution included Batch Control System, Gantry and Custom made bulk dry powder hoppers.

Inline Bulk Bag Unloader is pictured above!

Compact Bulk Bag Unloader is Pictured above!

No matter what the product, if it is dry, will flow and can be purchased in FIBC (Bulk Bags) then we can help you to both save money through risk reduction and production increases. Cement is just one example and one of the dustiest and most harmful to your staff's lungs, if you are using more than 25 tons per month of Cement (or any dry bulk product) then you should ask yourself "Is a Silo right for me?"

Reach out now if you have any questions or would like to know if you can get production gains effortlessly.

Config Inline.PNG)

Config 2-1.PNG)