Vibration Tables & Motors – What, Where & Why

Vibrating tables are found in many industrial processes, especially where powders and granulated dry materials are being handled.

They are also useful for removing entrapped air from liquids in casting applications, ensuring a uniform and complete void-free filling of the mould.

The vibration is made possible by special motors that have a weight mounted eccentrically, to throw the torque off balance. The centrifugal force from this ‘eccentric rotating mass’ (ERM) translates the rotary motion into an up-and-down / side-to-side oscillation. A ‘3-D’ multidirectional vibration or unidirectional vibration can be produced to suit the application, depending on the number and configuration of motors installed.

Vibrating tables are used in many packaging, testing and casting processes, whilst vibrating motors can be designed and built into other machines that require sections such as conveyors, hoppers, beds or tanks to vibrate.

Examples of vibration in different applications

Concrete product manufacture

The proper compaction of concrete is essential in controlling the uniform quality, density and strength of pre-cast concrete items such as pavers, posts, lintels, and beams. Vibrating the mould during the pour eliminates voids and air pockets, producing a solid and compact component with predictable strength.

Resin and plaster castings

Air bubbles can form in casting resins and plasters, either from the physical mixing stage or from off-gassing during product cure. Working on a vibrating table helps release these bubbles early on, preventing problems with aesthetics and performance in the finished article.

Metal foundry casting

Vibration tables can speed up and improve the process of making iron castings from foundry, or ‘green’ sand. By compacting the loose sand into every gap, the accuracy and finish of the subsequent casting is better.

Filling or emptying packaging or containers

Vibration speeds up the moving of bulk material from one vessel to another, and reduces wastage. Shaking out the material prevents clumping and bridging, enabling rapid, uninterrupted and complete emptying. Vibrating the packaging as it is filled, densifies and settles the material, allowing for full container loads which reduces transport, packaging material and storage costs (typically up to 20%-25%) when compared to non-settled filling.

Fatigue Testing

Accelerated aging and fatigue testing means a prototype can be tested against a standard or existing product to see how it reacts to multiple shocks and strain. It enables iterative engineering improvements by identifying weaknesses in structures.

Frequency, displacement, velocity and acceleration

The frequency and amplitude can be varied by the RPM (speed of motor) and the mass and distance from the shaft of the eccentric weight. Displacement and acceleration are largely down to motor size choice.

The vibration force can be calculated as shown in the formulas below:

Frequency (f) = RPM/60

Force = mass of the weight x weight’s distance from centre of shaft x f2

Basically, in simple terms this means the heavier the weight, the further off-balance it is, and the faster it spins…the greater the vibration.

Summary

Understanding and controlling vibration is important to many industrial machinery applications. Whilst unintentional vibration can cause (or signal) issues with rotary equipment, vibratory power can be harnessed to help move and process many challenging materials.

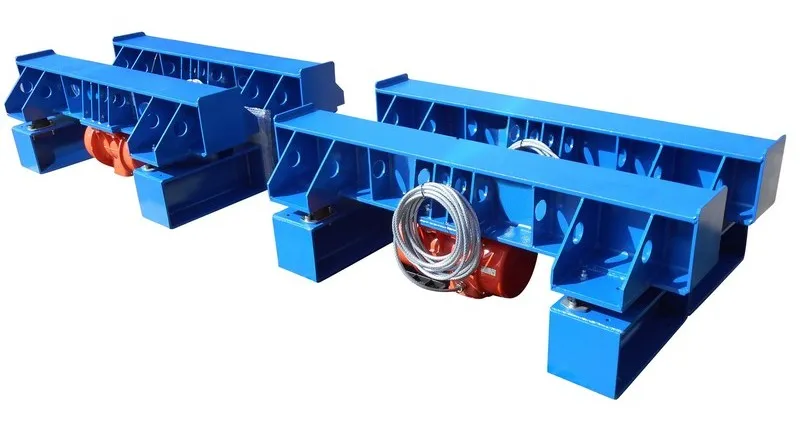

Vibration tables are workbenches for performing tasks that benefit from a powerful and controlled vibrating action. By engineering the characteristics of the vibrating motor, the table vibration can be matched so suit the application’s requirements.

Find out if a new vibration table, or an upgrade to your existing table’s vibrating motor configuration could revolutionise your workflow and output. Provide an overview by clicking here free of charge and we’ll give you access to our vibrating table solutions finder.