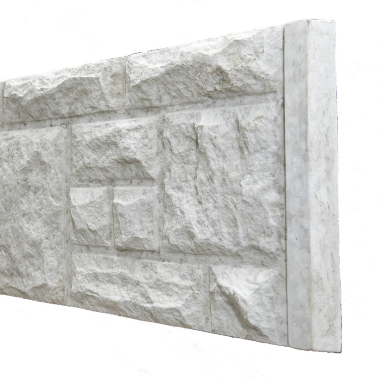

Concrete Fence Post and Concrete Gravel Board Moulds

If you are wanting to start making concrete fence post or concrete gravel boards then we have the complete solution for every budget - read on to see the whole scope. You can also read more here for our article on All The Things To Consider When Making Concrete Fenceposts and Gravel Boards

We supply Urethane Fence Post Moulds, Polypropylene Fence Post Moulds, ABS Gravel Board Moulds, Steel Mould Carriers, Timber Mould Holders and Steel Moulds. Our wide range of mould sizes and patterns will help you to start making money faster. We hold stock of most moulds allowing you to add to your stock quickly as market demand requires.

All of our Release Agents are suitable for our moulds and are a premium product giving the best release possible. We hold stock of this in 20l, 250L and 1000L IBC.

Spacer Clips

We hold large stocks of Rebar Spacer Clips for Concrete Fence posts and Concrete Gravel Boards. We stock and supply paving spacers and Tee Pins.

Spacers are available in box/bag format and are able to be purchased in mixed pallet or pallet quantities also, the later being the most cost effective way to buy.

Our clips are subtle and are designed for reduced brittleness saving you frustration and money.

Concrete Mixing

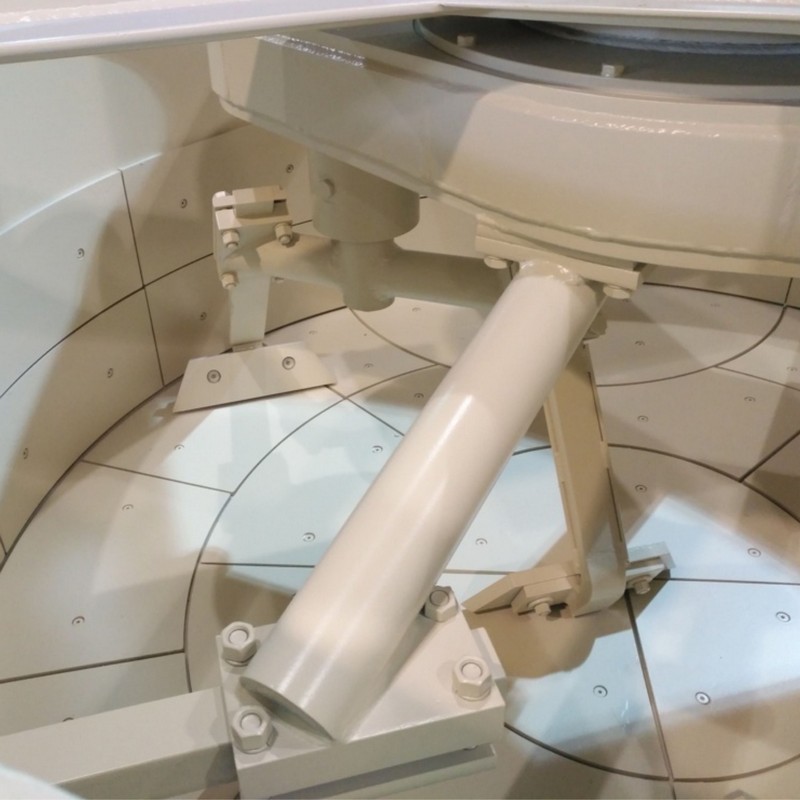

Choose your mixer.

You have the choice of Planetary, Drum, Pan or Forced Action Pan Mixers. Each of these mixers will mix the concrete for you but will do it at differing speeds and intensity.

Drum Mixers tend to be the most cost effective but Pan Mixers will mixer faster.

Forced Action Pan Mixers will do the best job but come in second highest price with Planetary Mixers being the highest.

Over the last 50 years we have found that there is two main categories of Concrete Mixer buyers - Well informed and Uninformed. We are not biased because we sell all mixer types but often time a mixer is chosen solely on initial purchase price and not any other consideration, this is not the best way to get good value for money. To help solve this problem we wrote the following Blog post on "Concrete Mixers (Which one is Best for Me? )" or see our mixer gallery for inspiration.

Rake off Table

Once you have mixed your concrete you need to get it out of the mixer and into the moulds. If you continue to run the mixer you not only cause unnecessary wear but you will continue to consume power. With a well design production flow and a rake off table you can potentially save 30% of your mixing power consumption.

Our rake off tables are designed to facilitate mould filling with out allowing the concrete to flow off the table unnecessarily. We also ensure that our mixers are made to integrate with the correct spacing between discharge and rake off table.

If you purchase the rake off table and the vibration table together you can easily tidy up and pack it underneath the rake off table.

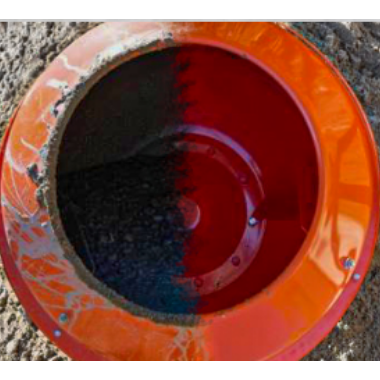

Vibration Table

Vibration Tables are a critical part of Concrete Fence Post Manufacturing and if you put too much vibration into the concrete you will not only make a mess but will have a lot of unnecessary noise and wear. Specifying the right table for each budget vs application is easy for us - we should know, we have done it for 47 years.

We hold stock of approximately 10 different vibration table designs allowing you quick delivery but also a table to help meet the budget and force required.

Cement Silo or Aggregate Storage

OK so we are getting things sorted and now we come to the cement and aggregate storage systems.

Unless you are investing with a large budget you probably wont be using our Moisture Correction and Batch Control Systems to correct any wet aggregates. One way to help keep product more consistent is to ensure your aggregates are not exposed to the elements as varying as they are. If you can keep them covered or in a aggregate hopper then you will help your production consistency. One major benefit of storing aggregates in a hopper is that any loose water is allowed to drain out and the aggregates will not be drenched. You can either convey the aggregates from the hopper of discharge them into a mixer via a scoop or directly.

The other thing to think about is Cement handling. This can either be done through 25kg bags, 1000kg bulk bags or direct from a cement silo. Generally if you are using 25 tons per month it then makes sense to invest in a silo because then the cement cost savings will nearly cover the repayments on the silo, of course invest before and then you can run your business faster and with more profit per piece of product produced.

In our blog post here you can read about the benefit of using either bulk bags or silo for cement storage and how to effortlessly handle 1ton bulk bags

We can help you work through the process of now vs later costings and help you to see the pro's and con's of each type of process for handling cement.

Dissolvacrete - Clean up concrete spills

Dissolvacrete is the first non-corrosive cleaning compound designed specifically to remove build-up from cement manufacturing, processing, handling and transportation equipment. The chemical does the work for you – and your equipment comes out clean, without any chipping or hammering!

Dissolvacrete can be applied with a low-pressure foaming sprayer, or brush and bucket. One application of the product will remove light build-up. Moderate to severe build-up may require regular applications over a period of days or weeks. Dilutions will vary depending on preference and frequency of use. Dissolvacrete can be applied with a low-pressure foaming sprayer, or brush and bucket. One application of the product will remove light build-up. Moderate to severe build-up may require regular applications over a period of days or weeks. Dilutions will vary depending on preference and frequency of use.

Book A Call With Us Today

Start by booking a call with us today to get the most cost effective and time saving equipment from us

Registered Address;

Unit 21 Prospect House,

Colliery Close, Staveley,

Chesterfield, England, S43 3QE

Call: 44(0)115 930 9068

Copyright © 2024 Peveril Group Ltd | All rights reserved. Terms & Conditions | Privacy Policy

Peveril Machinery is now part of Atlantic Pumps Group.

"Peveril, Peveril Machinery and OUR OTHER BRANDS" are a service mark and trading style of Peveril Group Ltd Product specifications are believed to be accurate at the time of original publication. Consumers should verify specifications suit their requirement rather than relying on information on this website, which is not intended to be a final specification.